Based on the comprehensive membrane protein production platform developed through years of experience, scientists from Creative Biostructure is able to provide custom Mempro™ pentameric ligand-gated ion channel production services using plant-based expression system.

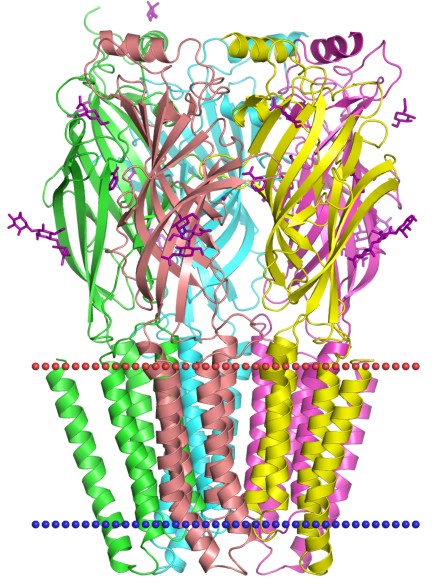

The pentameric ligand-gated ion channel (pLGIC), mediates fast synaptic communication (chemical transmission) through converting nerve signals into an electrical response, which belongs to a single neurotransmitter receptor superfamily. Actually, the pLGICs are a group of transmembrane ion channels that open to allow ions such as Na+, K+, Ca2+, or Cl− to pass through the cell membrane, which consist of five homologous subunits. It is well-known that the five subunits are composed of at least two different domains, including a transmembrane domain which forms the channel gate and the ion selective filter, and an extracellular domain which includes the ligand binding location (an allosteric binding site). In addition, pLGICs are divided into three classes: Cys-loop receptors, Ionotropic glutamate receptors and ATP-gated channels.

Figure 1. The structural model of gamma-aminobutyric acid receptor (GABA). (OPM Database)

Our Mempro™ membrane protein production platform based on plant system can produce recombinant membrane proteins with animal-free, low endotoxin, and low protease activity. Animal-free recombinant membrane proteins are very important for customers concerned with experimental variables caused by trace animal components or mammalian pathogens. Additionally, membrane proteins expressed by our plant system are free of animal components, serum, endotoxins and antibiotics as well as human or animal infectious agents or other endogenous mammalian contamination. Post-translational modification such as glycosylation and disulfide bonds can be introduced in plant system.

Creative Biostructure can employ various types of host plants such as Nicotiana benthamiana (tobacco), Medicago rativa (alfalfa), Arabidopsis thaliana (A. thaliana), potato, maize, barley and lettuce to perform membrane protein production services.

Key features of Mempro™ plant-based membrane protein production platform, including:

- Cost-effective

- Easy storage and distribution

- Environment friendly

- Free of infectious or toxic contaminants

- High scale-up capability

With the Mempro™ plant-based membrane protein production platform, Creative Biostructure is capable of overcoming the common difficulties encountered in cell-based expression system, such as misfolding, aggregation, inactivity, high endotoxin, poor stability and solubility, etc.

Creative Biostructure can also provide Mempro™ plant-based virus-like particles (VLPs) production services, Mempro™ animal-free recombinant protein production services and Mempro™ membrane protein production services. Please feel free to contact us for a detailed quote.

References:

A. Wiktorek-Smagur, et al. (2012). Green way of biomedicine – how to force plants to produce new important proteins. Transgenic Plants-Advances and Limitations, Chapter 3. doi: 10.5772/1409.

F. Junge, et al. (2008) Large-scale production of functional membrane proteins. Cellular Mol. Life Sci., 65 (11): 1729-1755.

J. A. Dent (2010). The evolution of pentameric ligand-gated ion channels. Adv. Exp. Med. Biol., 683: 11-23.

J. B. Corrie, et al. (2013). Gating of pentameric ligand-gated ion channels: structural insights and ambiguities. Structure, 21(8): 1271-1283.