Nuclear Magnetic Resonance (NMR) spectroscopy has emerged as a pivotal analytical technique in the beverage industry, offering unparalleled insights into the molecular composition of various drinks. Its non-destructive nature, combined with high reproducibility and minimal sample preparation, makes it an invaluable tool for quality control, authentication, and research and development. NMR spectroscopy exploits the magnetic properties of certain atomic nuclei. When placed in a magnetic field, these nuclei absorb and re-emit electromagnetic radiation at characteristic frequencies. By analyzing these frequencies, NMR provides detailed information about the molecular structure, dynamics, and environment of compounds within a sample.

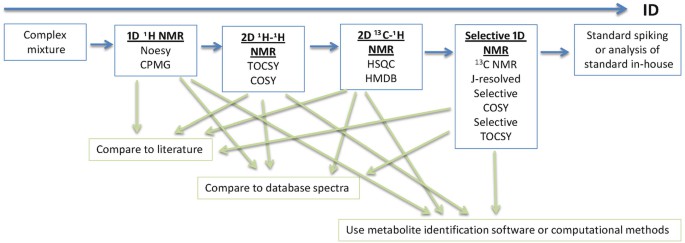

As specialists in NMR, Creative Biostructure provides tailored NMR services for the beverage industry, including comprehensive analysis of alcoholic beverages. Our advanced capabilities include a wide range of techniques, such as ¹H NMR, ¹³C NMR, homonuclear and heteronuclear 2D NMR spectroscopy, CP-MAS NMR, and more.

Applications of NMR in the Beverage Industry

| Type | Applications |

|---|---|

| Wine |

|

| Beer |

|

| Spirits |

|

| Fruit Juices |

|

| Soft Drinks |

|

| Coffee and Tea |

|

| Dairy and Plant-Based Beverages |

|

| Functional Beverages |

|

Quality Control and Assurance

NMR integrates into QC workflows to:

- Standardize Production: NMR is frequently employed to ensure uniformity in physicochemical properties such as ethanol content, pH, residual sugar, and organic acid profiles. For example, ¹H NMR can simultaneously quantify ethanol, glucose, fructose, lactic acid, and acetic acid in wine or kombucha, offering rapid validation of fermentation completeness and batch-to-batch reproducibility. This comprehensive profiling supports tight process control, especially for large-scale commercial operations where deviations may compromise flavor, safety, or shelf stability.

- Shelf-Life Testing: NMR spectroscopy aids in evaluating beverage stability during storage by tracking degradation markers. One key indicator is furfural, a furan derivative formed during Maillard reactions or thermal treatment, which is commonly monitored in pasteurized juices and flavored alcoholic beverages. Accumulation of such compounds, detected via ¹H or ¹³C NMR, correlates with sensory degradation and potential off-flavors, providing critical input for optimizing storage conditions and shelf-life labeling.

- Contaminant Screening: Grain-based beverages such as beer and whisky are susceptible to contamination from mycotoxins—secondary metabolites produced by fungi such as Fusarium and Aspergillus. Advanced NMR protocols can detect specific proton resonances or carbon signals characteristic of mycotoxins like deoxynivalenol and zearalenone. In some workflows, NMR is integrated with chemometric models to distinguish contaminated batches even when toxins are present at trace levels, ensuring both safety and regulatory compliance.

Authenticity and Fraud Detection

Beverage fraud costs billions annually. NMR addresses this via:

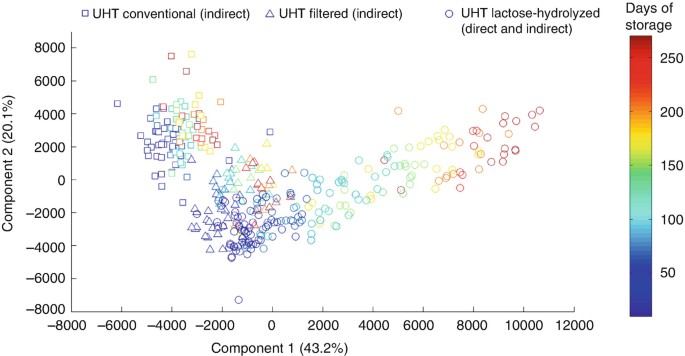

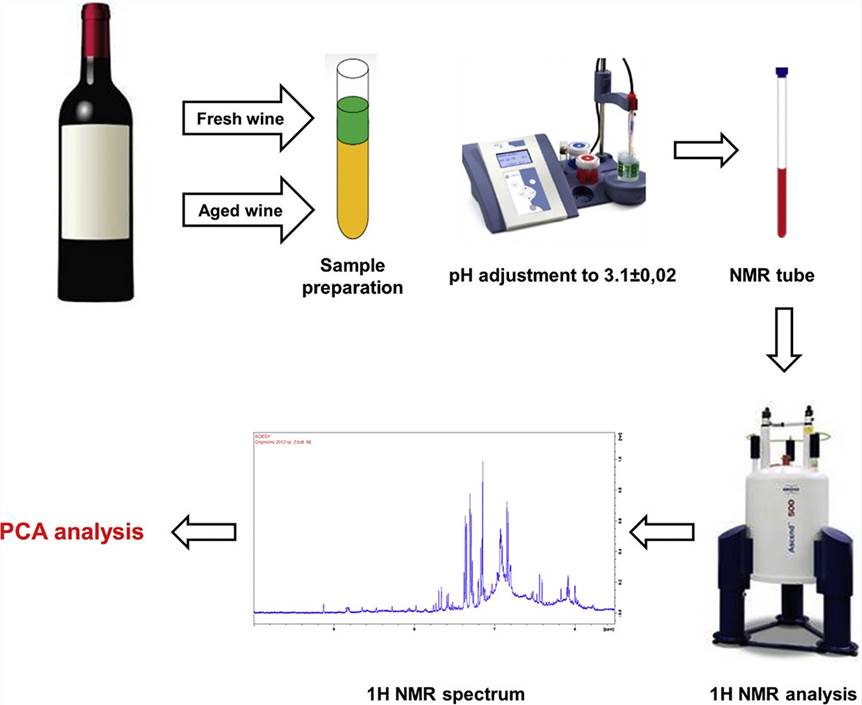

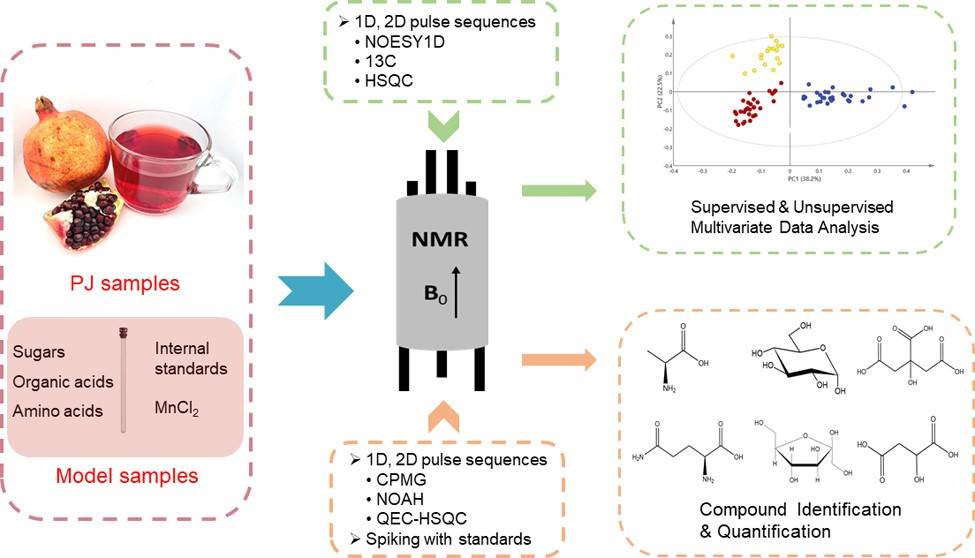

- Metabolomic Fingerprinting: Using ¹H NMR in conjunction with multivariate statistical techniques such as Principal Component Analysis (PCA) and Partial Least Squares Discriminant Analysis (PLS-DA), producers can classify beverages based on geographic origin, botanical variety, or processing methods. For example, wine authenticity can be verified by comparing the profile of polyphenols, amino acids, and organic acids against regional spectral libraries. This has been successfully implemented in distinguishing Tuscan wines from Spanish or Chilean counterparts.

- Organic Certification: Authenticating organically labeled juices and teas involves verifying the absence of synthetic agrochemical residues and assessing the presence of higher natural antioxidant levels. Studies show that organic beverages often contain elevated levels of polyphenols and certain flavonoids, which are quantifiable via NMR. Discriminant analysis applied to NMR spectra can robustly differentiate organic from conventional products, thereby supporting certification bodies and export requirements.

- Counterfeit Identification: NMR is highly effective in identifying synthetic alcohol or spirits diluted with water or blended with inferior base liquors. Diagnostic spectral features such as the ethanol CH3 and CH2 group resonances (~1.1 and ~3.6 ppm) can be analyzed in relation to congener and fusel oil profiles. Additionally, 2H NMR and site-specific natural isotope fractionation (SNIF-NMR) provide isotopic signatures that distinguish ethanol derived from fermentation versus petrochemical synthesis—essential for regulatory verification in premium spirits.

Process Optimization and Innovation

- Fermentation Monitoring and Control: Real-time or time-resolved NMR enables kinetic monitoring of sugar-to-ethanol conversion during fermentation. By quantifying residual glucose and fructose alongside ethanol and by-products (e.g., glycerol, succinic acid), NMR allows producers to fine-tune parameters such as yeast strain selection, temperature profiles, and nutrient supplementation. This reduces batch cycle times and enhances consistency in alcoholic beverage production.

- Flavor and Aroma Development: Craft beverage innovation increasingly relies on profiling key flavor volatiles, including esters (e.g., ethyl acetate, isoamyl acetate), higher alcohols, and terpenes (e.g., linalool, limonene). NMR, particularly when coupled with solid-phase microextraction (SPME) or 2D correlation spectroscopy (COSY, HSQC), identifies and quantifies these compounds with high precision. These insights are critical in developing differentiated flavor profiles in specialty coffees, botanical gins, and non-alcoholic malt beverages.

- Waste Reduction and Sustainability: NMR helps identify inefficiencies in raw material extraction, such as incomplete release of caffeine or theanine in tea leaves or polyphenols in coffee beans. By assessing extraction kinetics and solute profiles, process engineers can adjust brewing conditions, solvent compositions, or filtration parameters to minimize waste and maximize yield—aligning with circular economy goals and sustainable sourcing commitments.

Regulatory Compliance and Standards Alignment

As regulatory frameworks for food and beverage safety continue to evolve, NMR plays an increasingly important role in ensuring compliance with international and regional standards.

- Label Accuracy Verification: NMR offers objective quantification of key nutritional and compositional claims. For example, claims such as "no added sugar" can be validated by measuring sucrose, glucose, and fructose concentrations. Similarly, the absence of gluten-derived peptides in "gluten-free" beers made from barley can be assessed using ¹H and ¹³C NMR combined with spectral libraries and chemometric comparison.

- Safety Assurance and Legal Limits: In the spirits sector, methanol contamination presents a serious health hazard. NMR can accurately detect and quantify methanol down to 0.01% w/v, satisfying regulatory thresholds such as those imposed by EU Regulation 2019/787, which limits methanol to below 0.1% in most distilled beverages. By distinguishing methanol from structurally similar compounds like ethanol and propanol, NMR avoids false positives common to less selective analytical techniques.

- Global Trade and Export Certification: Compliance with international standards such as ISO/IEC 17025 or Codex Alimentarius requires reproducible, validated analytical techniques. NMR meets these criteria and is recognized by several regulatory agencies as a reliable method for verifying compositional integrity. Its use in origin certification and contaminant screening supports export documentation and customs clearance, especially for premium or sensitive beverage categories.

Select Service

Case Studies

Case 1: The effects of sulphur dioxide on wine metabolites: New insights from ¹H NMR spectroscopy based in-situ screening, detection, identification and quantification

Sulphur dioxide (SO2) is widely used in the wine industry for its antimicrobial and antioxidant properties, yet it reacts with key wine metabolites—such as acetaldehyde, diacetyl, pyruvic acid, and furfural—to form various adducts over time. This dynamic chemical behavior complicates ¹H NMR spectroscopic analysis, as metabolites may appear in their native form, as O-adducts, or as S-adducts depending on SO2 concentration. To address this, a new methodology has been proposed to systematically identify these SO2-derived species in wine using ¹H NMR. Model wine solutions containing 0–150 mg/L SO2 were analyzed, revealing complete conversion of acetaldehyde to its hydroxysulfonate form at 100 mg/L SO2. This approach was validated using ten commercial Moscato wine samples, showing excellent agreement with results obtained by OIV standard methods, thereby confirming ¹H NMR's capability to track structural transformations induced by SO2 under regulatory limits.

Figure 1. ¹H NMR spectra of acetaldehyde; Expansion of methyl region. A: without SO2, B: SO2 50 mg/L, C: SO2 100 mg/L, D: SO2 150 mg/L. (Cassino et al., 2021)

Figure 1. ¹H NMR spectra of acetaldehyde; Expansion of methyl region. A: without SO2, B: SO2 50 mg/L, C: SO2 100 mg/L, D: SO2 150 mg/L. (Cassino et al., 2021)

Case 2: Compositional analysis of four kinds of citrus fruits with an NMR-based method for understanding nutritional value and rational utilization: from pericarp to juice

This study applied NMR spectroscopy combined with pattern recognition to analyze both juice and pericarp components of four major citrus varieties—lemon, dekopon, sweet orange, and pomelo. A total of 62 compounds in the juices and 87 in the pericarps were identified and quantified. Multivariate statistical analyses successfully distinguished citrus varieties and identified characteristic chemical markers for each. The findings enhance understanding of citrus fruits' nutritional and potential medicinal value, particularly highlighting the underutilized pericarp. Moreover, this approach offers a valuable analytical framework for fruit traceability, adulteration detection, and comprehensive compositional profiling in other fruit products.

Figure 2. The superimposed 850 MHz ¹H-NMR spectra of the four varieties of citrus juices (A) and pericarps (B). For clarity, the spectral regions of δ 0.5–3.0 were vertically magnified 15 times and 5 times relative to the spectral regions of δ 3.0–5.5 for the juices and pericarps, respectively. The spectral regions of δ 3.0–5.5 of the lemon juice were vertically magnified 4 times relative to the same spectral region of the other three citrus juices. The spectral regions of δ 5.5–10.0 were vertically magnified 600 times and 100 times relative to the spectral regions of δ 3.0–5.5 for the juices and pericarps, respectively, among which the spectral regions of δ 6.00–6.30, δ 6.90–7.00 and δ 7.31–7.35 for the pericarps were only magnified 10 times. These U on the spectra indicate the unassigned signals. (Pei et al., 2022)

Figure 2. The superimposed 850 MHz ¹H-NMR spectra of the four varieties of citrus juices (A) and pericarps (B). For clarity, the spectral regions of δ 0.5–3.0 were vertically magnified 15 times and 5 times relative to the spectral regions of δ 3.0–5.5 for the juices and pericarps, respectively. The spectral regions of δ 3.0–5.5 of the lemon juice were vertically magnified 4 times relative to the same spectral region of the other three citrus juices. The spectral regions of δ 5.5–10.0 were vertically magnified 600 times and 100 times relative to the spectral regions of δ 3.0–5.5 for the juices and pericarps, respectively, among which the spectral regions of δ 6.00–6.30, δ 6.90–7.00 and δ 7.31–7.35 for the pericarps were only magnified 10 times. These U on the spectra indicate the unassigned signals. (Pei et al., 2022)

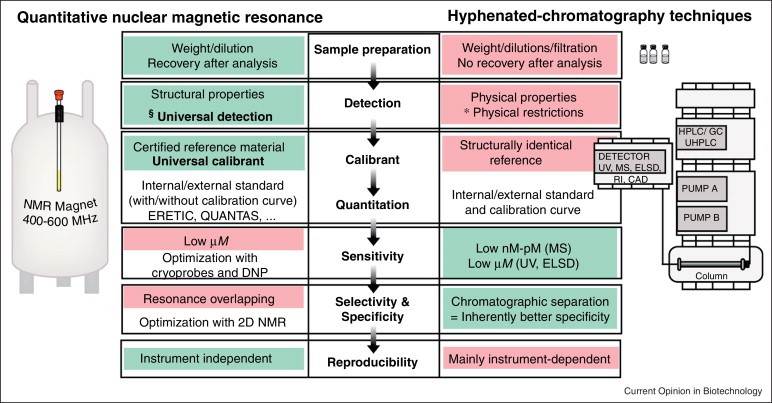

Advantages of NMR in Beverage Analysis

- Non-Destructive: Samples remain intact post-analysis, allowing for further testing if necessary.

- Minimal Sample Preparation: Reduces analysis time and potential sample contamination

- High Reproducibility: Ensures consistent results across multiple analyses

- Comprehensive Profiling: Simultaneously detects a wide range of compounds, providing a holistic view of the sample's composition.

Challenges and Considerations

While NMR offers numerous advantages, certain challenges persist:

- Cost: High-field NMR instruments are expensive to acquire and maintain.

- Sensitivity: NMR is less sensitive compared to techniques like mass spectrometry, potentially limiting its detection of low-abundance compounds.

- Expertise Required: Interpreting NMR spectra necessitates specialized knowledge, which may not be readily available in all settings.

Future Perspectives

Advancements in NMR technology, such as the development of benchtop NMR instruments, are making the technique more accessible to the beverage industry. These compact devices offer many of the benefits of traditional NMR systems at a fraction of the cost and complexity. As technology continues to evolve, NMR is poised to play an even more integral role in ensuring the quality and authenticity of beverages worldwide.

Whether it's authenticity, flavor profiling, or quality control, NMR is redefining standards in the beverage industry. Taste the science of precision. Contact us to learn how our NMR solutions can enhance your beverage testing workflows.

References

- Cassino C, Tsolakis C, Gulino F, Vaudano E, Osella D. The effects of sulphur dioxide on wine metabolites: New insights from ¹H NMR spectroscopy based in-situ screening, detection, identification and quantification. LWT. 2021;145:111296. https://doi.org/10.1016/j.lwt.2021.111296

- Kidrič J. Chapter 5 NMR study of beverages. In: Annual Reports on NMR Spectroscopy. Vol 64. Elsevier; 2008:161-171. https://doi.org/10.1016/S0066-4103(08)00005-7

- Kuballa T, Brunner TS, Thongpanchang T, Walch SG, Lachenmeier DW. Application of NMR for authentication of honey, beer and spices. Current Opinion in Food Science. 2018;19:57-62. https://doi.org/10.1016/j.cofs.2018.01.007

- Pei Y, He C, Liu H, Shen G, Feng J. Compositional analysis of four kinds of citrus fruits with an NMR-based method for understanding nutritional value and rational utilization: from pericarp to juice. Molecules. 2022;27(8):2579. https://doi.org/10.3390/molecules27082579

- Tabago MKAG, Calingacion MN, Garcia J. Recent advances in NMR-based metabolomics of alcoholic beverages. Food Chemistry: Molecular Sciences. 2021;2:100009. https://doi.org/10.1016/j.fochms.2020.100009