Nuclear Magnetic Resonance (NMR) spectroscopy, a method rooted in quantum physics and electromagnetic resonance, has become indispensable across the petrochemical value chain—from subsurface exploration to final product quality analysis. Its non-destructive nature, rapid analysis, and ability to provide molecular-level insights have made it central to following aspects: Determining reservoir fluid and rock properties; Characterizing crude oil and refined fuels; Ensuring product consistency and purity; and Analyzing catalysts and polymer systems.

Creative Biostructure offers comprehensive petrochemical analysis powered by advanced NMR technologies. Our services include the analysis and structural characterization of crude oil and refined products, catalyst performance profiling, and polymer characterization—leveraging both solution-state and solid-state NMR. In this article, we provide a technical and detailed overview tailored to professionals, illustrating how NMR supports exploration, refining, research, and quality assurance within the petrochemical industry.

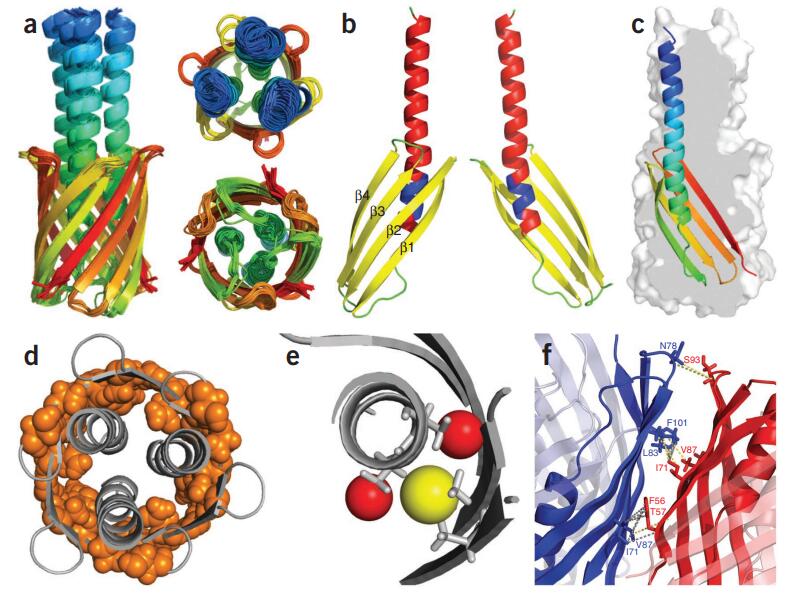

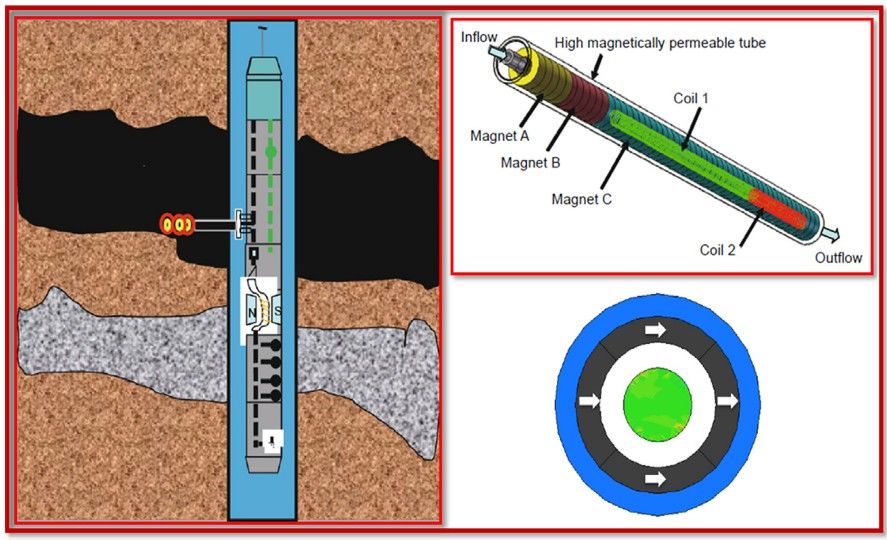

Figure 1. NMR fluid analyzer applied to petroleum industry. (a) Applications to exploration, exploitation, transportation and refining. (b) Sketch map of the system, permanent magnets generate a homogeneous magnetic field inside the instrument. Incorporated with the circuit, the system gets the NMR responses shown in (c) (d) Some representative properties from the measurement results. (Liao et al., 2021)

Figure 1. NMR fluid analyzer applied to petroleum industry. (a) Applications to exploration, exploitation, transportation and refining. (b) Sketch map of the system, permanent magnets generate a homogeneous magnetic field inside the instrument. Incorporated with the circuit, the system gets the NMR responses shown in (c) (d) Some representative properties from the measurement results. (Liao et al., 2021)

NMR in Hydrocarbon Exploration

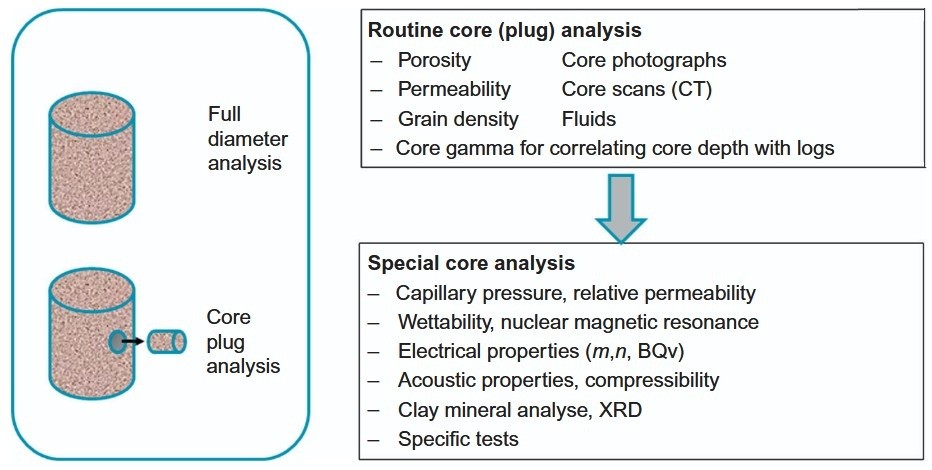

NMR has become a powerful tool in hydrocarbon exploration, particularly in reservoir characterization and core analysis. Its ability to non-invasively probe the fluid content and pore structure of rocks provides crucial insights into reservoir quality, hydrocarbon recoverability, and flow dynamics. The two primary applications are core-based laboratory NMR and in-situ downhole NMR logging.

Core Analysis & Rock Porosity

In core analysis, NMR is applied to cylindrical rock samples retrieved from drilling operations. These samples, often several centimeters in diameter and up to a meter in length, undergo detailed physical and chemical evaluation in the lab. Among these techniques, low-field NMR core analyzers have become standard tools.

Figure 2. Core analysis directed on reservoir properties. (Schön, 2015)

Figure 2. Core analysis directed on reservoir properties. (Schön, 2015)

How It Works?

Core NMR measurements are based primarily on the transverse relaxation time (T2), which reflects how quickly the signal from hydrogen nuclei in pore fluids decays after the excitation pulse. Since T2 is sensitive to the surface-to-volume ratio of the pores, it provides indirect but powerful information about pore geometry and fluid mobility.

Key Parameters Measured by Core NMR

- Porosity

- Free vs. bound fluid volumes

- Pore size distribution

- Fluid permeability

Practical Applications

- Reservoir evaluation and ranking

- Capillary pressure correlation

- Hydraulic fracturing optimization

- Enhanced oil recovery (EOR) screening

- Shale gas/oil assessment (via T2 cutoff shifts and fluid typing)

Log Integration (Downhole NMR Tools)

While core analysis delivers high-resolution data at discrete points, modern oilfield operations are increasingly turning to in-situ NMR logging for continuous formation evaluation along the borehole. These logging tools operate at relatively low magnetic field strengths (typically around 0.1–0.5 T) and can be deployed either on wireline or as part of logging-while-drilling (LWD) systems. By acquiring real-time measurements directly within the wellbore, NMR logging provides valuable insights into porosity, fluid saturation, and formation permeability that complement core and conventional log data.

Figure 3. The illustration of in-situ NMR fluid analysis laboratory working at downhole. (Liao et al., 2021)

Figure 3. The illustration of in-situ NMR fluid analysis laboratory working at downhole. (Liao et al., 2021)

How It Works?

Downhole NMR logging tools generate and detect magnetic resonance signals from hydrogen nuclei in formation fluids. Despite operating at much lower magnetic fields than lab NMR (to fit in a borehole), they can still generate T1 and T2 relaxation distributions using advanced pulse sequences.

- T1 Measurement: Provides insight into fluid types—short T1 typically corresponds to heavy oils or bound water.

- T2 Measurement: Used for porosity and fluid mobility; analogous to core measurements.

Key Reservoir Parameters from Logging

- Total porosity

- Hydrocarbon typing and viscosity

- Permeability and productivity index (PI)

- Saturation profiling

Practical Applications

- Unconventional reservoirs

- Heavy oil reservoirs

- Carbonate characterization

- Formation evaluation in complex clastic sequences

NMR in Refinery and Petrochemical Processing

The refining and petrochemical sectors demand fast, precise, and non-destructive analytical techniques to monitor composition, optimize production, ensure quality control, and comply with regulatory standards. NMR spectroscopy, particularly 1H NMR, plays a central role in meeting these demands by providing detailed insight into molecular composition, hydrogen environments, and physical properties of petroleum-derived products. NMR applications span from low-field benchtop instruments used for routine quality control to high-resolution spectrometers used for structural elucidation and fuel property prediction.

Wax (Paraffin) Content Analysis

Paraffinic hydrocarbons—particularly long-chain n-alkanes—are prone to crystallization at low temperatures, leading to wax precipitation. This poses significant operational challenges, including increased pipeline viscosity, blockage in cold environments, and compromised flow assurance. The industry must continuously monitor wax content in crude oil, diesel, lubricants, and intermediates to maintain flow efficiency and ensure that fuels meet cold-weather performance specifications (e.g., cloud point, pour point).

How It Works?

Low-field time-domain NMR (TD-NMR) systems offer a rapid, solvent-free, and non-destructive method for quantifying wax content. The method involves:

- Sample preparation: Minimal—often only temperature conditioning

- 1H Relaxation-based analysis: Differentiates wax crystals (rigid protons, fast T2 relaxation) from mobile oil components (slower T2)

- Measurement Time: Typically, under 2 minutes per sample

Applications

- Upstream: Crude oil wax profiling for flow assurance modeling

- Midstream: Pipeline integrity programs

- Downstream: Monitoring lubricating oil base stock quality, wax separation efficiency, and cold flow additives in diesel

Aromaticity and Functional Group Profiling

Aromatic content in fuels and feedstocks affects combustion quality, engine deposits, and emissions, and is tightly regulated. Aromatics are also critical building blocks in the petrochemical industry—especially benzene, toluene, and xylene (BTX). The presence of specific functional groups (olefins, esters, halogens, and amines) also informs cracking efficiency, blending performance, catalyst compatibility, and environmental compliance.

Figure 4. Benzene, toluene, and xylenes (BTX) in petrochemicals. (Adapted from Wegelin and Meier, 2024)

Figure 4. Benzene, toluene, and xylenes (BTX) in petrochemicals. (Adapted from Wegelin and Meier, 2024)

How It Works?

Benchtop high-resolution NMR spectrometers offer robust aromaticity profiling and functional group identification:

- 1H NMR: Differentiates between proton environments—aromatic (~6.5–8 ppm), olefinic (~4.5–6 ppm), aliphatic (~0.5–2.5 ppm)

- 13C NMR (optional): Enhances carbon-based structure elucidation for complex mixtures

- 19F, 31P, 11B NMR: Used for specialty chemicals and additives detection

Key Parameters Measured by Benchtop High-Resolution NMR

- Total aromatic hydrogen content

- Relative aromaticity index (RAI)

- Degree of saturation (aliphatic vs. olefinic)

Applications

- BTX separation and analysis

- Olefins monitoring in FCC outputs

- Polymer feedstock characterization

- Functionalized fuel additive profiling

- Detection of oxygenates (e.g., MTBE, ethanol) and halogenated compounds

Fuel Property Prediction

Traditional methods of determining fuel properties, such as cetane number, flash point, pour point, viscosity, and density, often require multiple instruments, time-consuming sample preparation, flammable or hazardous chemicals, and expert operators.

However, the 1H NMR spectrum of a fuel contains detailed structural information that correlates with its macroscopic physical and performance characteristics. Recent advances in chemometric modeling and multivariate calibration have enabled rapid prediction of key fuel parameters from a single NMR scan.

How It Works?

Using 1H high-field or benchtop NMR in conjunction with partial least squares (PLS) regression or principal component analysis (PCA), researchers and industry professionals can develop calibration models for:

- Cetane number (diesel): Linked to the ratio of linear paraffins to branched or aromatic compounds

- Octane number (gasoline): Influenced by the aromatic and olefinic content

- Flash point & pour point: Correlated with molecular weight distribution and branching

- Viscosity & density: Related to chain length, degree of saturation, and heteroatom content

Applications

- Blending control in refineries

- Quality assurance for transportation fuels

- Custom fuel formulation for aviation or racing

- Renewable diesel and biofuel certification

- Lubricant formulation and aging monitoring

NMR for Quality Control and Product Testing

The petrochemical industry places high demands on analytical precision, speed, and non-destructive testing methods. NMR spectroscopy, with its ability to probe molecular structures and physical environments with exceptional resolution and reproducibility, is increasingly employed as a frontline tool in quality control (QC) and product validation.

Gasoline, Diesel, and Aviation Fuels

Fuel performance, efficiency, and regulatory compliance hinge on key compositional metrics, including hydrocarbon class distribution, hydrogen content, and additive integrity. NMR offers a rapid, solvent-free method to monitor these parameters, often in a single analytical run.

Applications

- Hydrogen Content Analysis

- Aromaticity and Aliphatic Ratio

- Additive Verification and Blend Homogeneity

Polymers and Lubricants

Polymers and lubricants—derived from petrochemical feedstocks—often exhibit complex, branched, or highly substituted structures. NMR is one of the few techniques that can directly interrogate these structures at the atomic level without degradation or extensive processing.

Applications

- Polymer branching, tacticity, end-groups

- Connectivity mapping for complex lubricants

- Detection of structural modifications

Additive and Contaminant Testing

Petroleum-derived products often require complex additive packages to meet performance specifications and extend functional lifespans. Over time, these additives degrade or interact with contaminants such as moisture, acids, or particulates. NMR is uniquely positioned to distinguish intact additives from their breakdown products, as well as to identify contamination events.

Applications

- ZDDP and anti-wear additives

- Oxidation and nitration products

- Contaminant identification

Waxes, Emulsions, and Bitumen

Heavy petroleum fractions such as waxes, emulsions, and bituminous residues present major analytical challenges due to their high viscosity, heterogeneity, and complex phase behavior. Time-Domain NMR (TD-NMR) and relaxation-based methods are particularly well-suited to these matrices.

Applications

- Wax quantification and behavior

- Emulsion stability and droplet size

- Bitumen/asphaltene analysis

Select Service

Advanced NMR Techniques

| Technique | Description |

|---|---|

| Time Domain NMR (TD-NMR) | TD-NMR uses relaxation measurements (T2, T1) to analyze bulk properties—no chemical shifts, but quantitative measures of porosity, phase content, and droplet sizes. |

| Benchtop NMR | Compact, cryogen-free instruments enable onsite or lab-level monitoring—proton, carbon, and occasional 31P or 19F detection for QC and R&D. |

| Multi-Nuclear Approaches | Beyond 1H and 13C, nuclei such as 31P (additives), 19F (fluorine-containing components), and 11B offer detailed chemical profiling for functionality and contaminant analysis. |

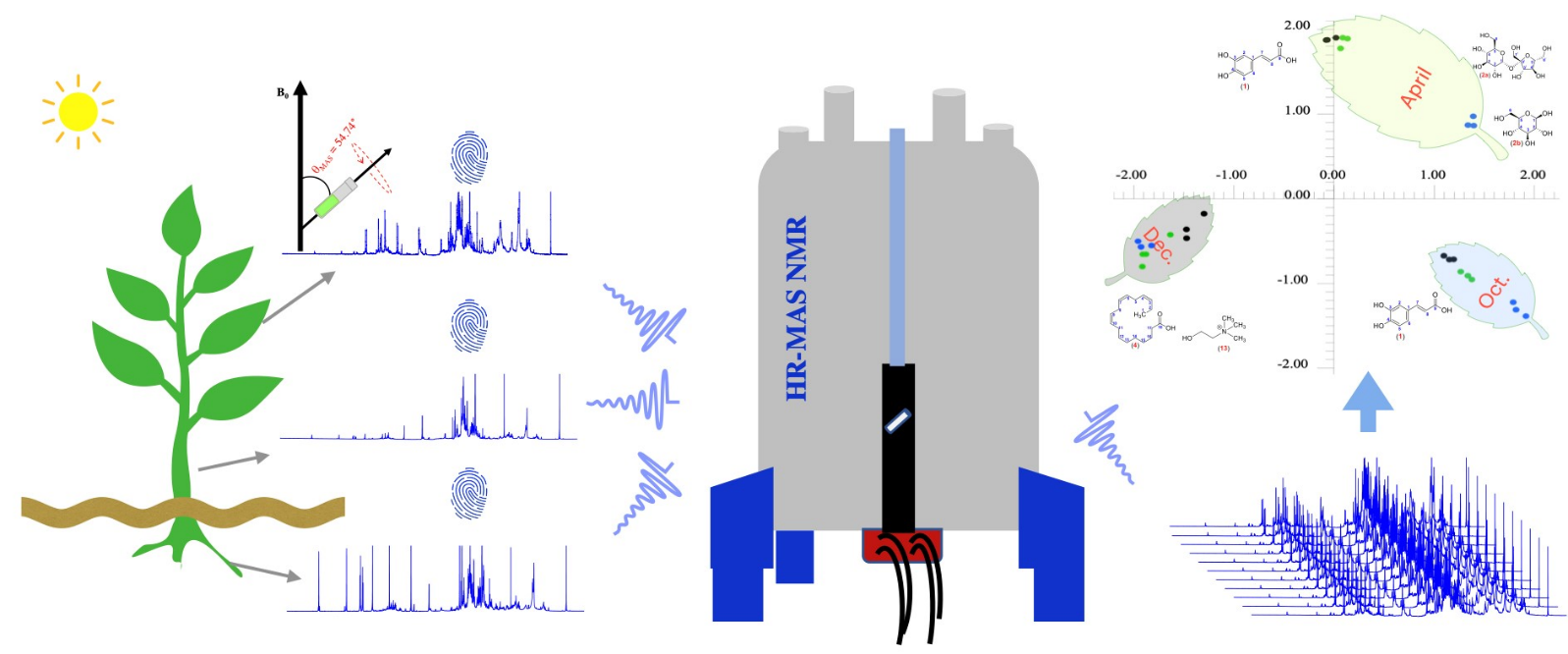

| Solid-State NMR Techniques | Techniques like MAS (Magic Angle Spinning) with solid-state spectra reduce broadening and improve structural analysis on catalysts, sediments, and heavy oils. |

| Hyperpolarization Techniques (DNP) | DNP enhances sensitivity by transferring polarization from electrons to nuclei—enabling detection of minor species, surface-bound molecules, or low-concentration impurities. |

Challenges and Technological Developments

- Sensitivity vs. Instrumentation: Low-field systems are convenient and portable but may lack sensitivity. Hyperpolarization and optimized hardware (like cryoprobes) help bridge this gap.

- Spectral Complexity: Complex hydrocarbon mixtures produce overlapping resonances. Solutions include high resolution 2D NMR, chemometric deconvolution, and solid-state MAS techniques.

- Standardization & Scalability: Industry-wide NMR methods require cross-vendor standardization—especially for QC parameters aligned to ASTM protocols (e.g., ASTM D7171).

- Non-Clean Samples: High-viscosity, heavy oil, or emulsions can complicate data. Robust sampling, controlled temperature, and pre-treatment help improve reliability, as highlighted by bench-top case anecdotes.

Case Studies

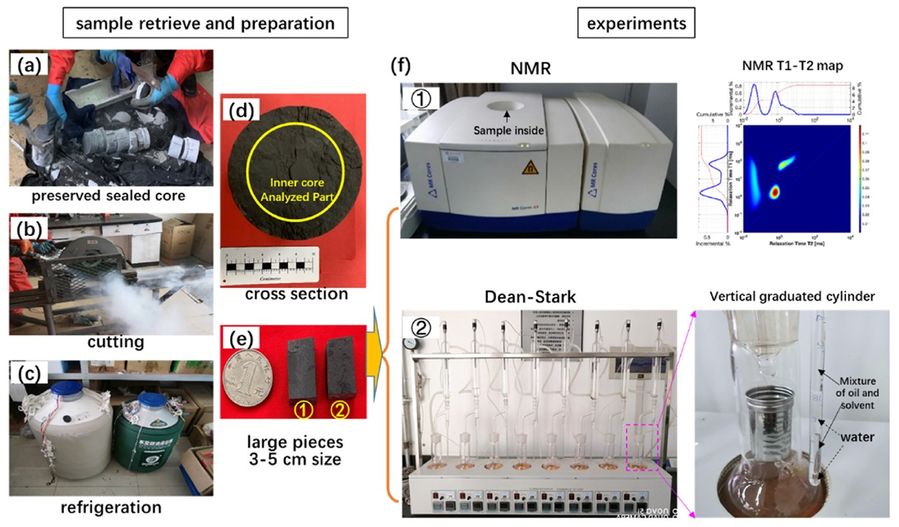

Case 1: 2D NMR as a potential approach to characterize preserved cores

The study explores a fast, non-destructive method to determine in situ hydrocarbon content and distribution in shale oil reservoirs using 2D NMR T1–T2 mapping. Unlike traditional solvent or thermal extraction methods, which are time-consuming and lack detail on oil-water occurrence, the proposed technique accurately evaluates porosity, fluid saturation, and evaporative loss in preserved shales.

Researchers tested 60 shale samples from the Qingshankou Formation (Songliao Basin, China), comparing NMR results to Dean–Stark extraction. The NMR-based oil content correlated strongly with traditional results when calibrated with crude oils of varying maturities. The method revealed that oil tends to reside in larger pores, while water is more distributed in smaller pores. Over 150–200 hours of air exposure, total oil and water content dropped by ~80%, with free oil content decreasing by 92%, but absorbed oil remained relatively stable.

The study highlights 2D NMR as a rapid (5-minute), reliable tool for analyzing fluid content, distribution, and maturity trends in shales, offering a clear advantage for evaluating samples prone to fast evaporation.

Figure 5. Schematic diagram of preserved shale sample preparation and experiments in this study. (Li et al., 2022)

Figure 5. Schematic diagram of preserved shale sample preparation and experiments in this study. (Li et al., 2022)

Case 2: Hydrocarbon profiling in gasoline via 1H-NMR

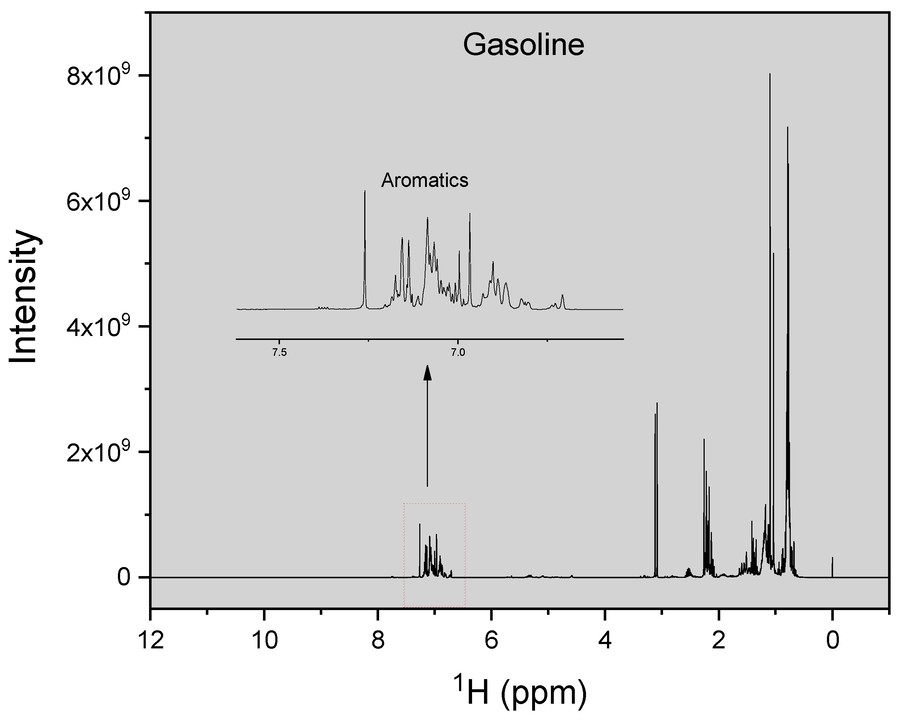

Gasoline, a key distillate fuel for spark-ignited engines, is composed of hundreds of hydrocarbons of varying structures. To simplify its complexity, molecules can be categorized into a limited number of functional groups. In this study, high-resolution 1H NMR spectroscopy was used to identify and quantify these groups in a gasoline sample. The fuel's composition was described using six major hydrocarbon group types: paraffinic (CH, CH2, CH3), naphthenic (CH–CH2), and aromatic (C–CH). These group profiles were then used to predict critical fuel properties, such as research and motor octane numbers (RON, MON), derived cetane number (DCN), threshold sooting index (TSI), and yield sooting index(YSI), providing an efficient alternative to costly experimental testing.

Figure 6. 1H-NMR spectra of the gasoline sample. (Abdul Jameel, 2021)

Figure 6. 1H-NMR spectra of the gasoline sample. (Abdul Jameel, 2021)

In summary, NMR stands as a cornerstone technology in the petrochemical industry, delivering actionable insights from subsurface through to final product. With cutting-edge equipment and extensive expertise, Creative Biostructure specializes in NMR petrochemical analysis. Contact us today to learn more—let's fuel your success!

References

- Abdul Jameel AG. Identification and quantification of hydrocarbon functional groups in gasoline using 1H-NMR spectroscopy for property prediction. Molecules. 2021;26(22):6989.

- De Paulo EH, Dos Santos FD, Folli GS, et al. Determination of gross calorific value in crude oil by variable selection methods applied to 13C NMR spectroscopy. Fuel. 2022;311:122527.

- Elsayed M, Isah A, Hiba M, et al. A review on the applications of nuclear magnetic resonance (NMR) in the oil and gas industry: laboratory and field-scale measurements. J Petrol Explor Prod Technol. 2022;12(10):2747-2784.

- Li J, Wang M, Fei J, et al. Determination of in situ hydrocarbon contents in shale oil plays. Part 2: Two-dimensional nuclear magnetic resonance (2D NMR) as a potential approach to characterize preserved cores. Marine and Petroleum Geology. 2022;145:105890.

- Liao G, Luo S, Xiao L. Borehole nuclear magnetic resonance study at the China university of petroleum. Journal of Magnetic Resonance. 2021;324:106914.

- Liao GZ, Chen WL, Zong FR, et al. NMR fluid analyzer applying to petroleum industry. Pet Sci. 2021;18(1):54-91.

- Schön JH. Rocks—their classification and general properties. In: Developments in Petroleum Science. Vol 65. Elsevier; 2015:1-19.

- Wegelin S, Meier MAR. Bio-based aromatics for chemicals and materials: Advances in renewable drop-in and functional alternatives. Current Opinion in Green and Sustainable Chemistry. 2024;47:100931.