MicroED Structure Determination Service for Novel Materials

In the fast-paced fields of reticular chemistry and materials science, waiting for large single crystals to grow is often the bottleneck that stalls innovation. Conventional Single-Crystal X-ray Diffraction (SC-XRD) requires crystals of significant size and quality—a luxury not always available for novel synthesized materials.

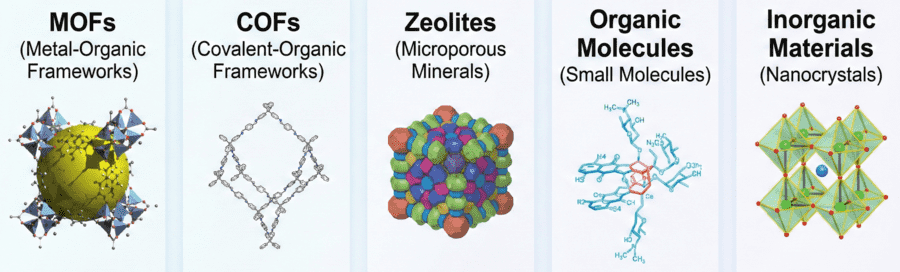

Creative Biostructure removes this hurdle. Leveraging our advanced Microcrystal Electron Diffraction (MicroED) platform, we provide a definitive structural determination solution for samples that are too small for X-ray (< 1 µm) or only available as microcrystalline powders. By utilizing the strong interaction between electrons and matter, we can determine the 3D atomic structure of MOFs, COFs, Zeolites, and organic small molecules with speed, precision, and minimal sample volume.

Visualizing the Unseeable with the MicroED Advantage

Unlike X-rays, electrons interact with matter roughly 10,000 times more strongly. This physical property allows MicroED to yield high-quality diffraction data from nanocrystals as small as 100 nm—sizes that would produce zero signal in a standard X-ray diffractometer.

We bridge the gap between powder diffraction (which often yields ambiguous results) and single-crystal diffraction, offering a direct "visual" of the atomic lattice, bonding connectivity, and pore architecture.

Key Capabilities

- Resolution: Consistently achieving atomic resolution (typically 0.8Å - 1.0Å), sufficient for ab initio structure solution.

- Sample Efficiency: Requires only sub-milligram quantities of powder.

- Speed: Data collection takes minutes per crystal, with full structure elucidation often completed within days.

Figure 1. Schematic overview of MicroED applications in new-material structure identification. (Creative Biostructure)

Figure 1. Schematic overview of MicroED applications in new-material structure identification. (Creative Biostructure)

MicroED Applications in Reticular Chemistry and Pharmaceuticals

Our interdisciplinary team adapts data collection strategies based on the specific beam sensitivity and vacuum stability of your material.

| Porous Frameworks (MOFs, COFs, HOFs) | Metal-Organic Frameworks and Covalent-Organic Frameworks often crystallize as micro-powders. We specialize in:

|

| Advanced Nanomaterials (MXenes & Zeolites) | For inorganic materials and 2D functionalized sheets (like graphene derivatives or MXenes), MicroED provides insights into layer stacking and surface terminations that are difficult to resolve via TEM imaging alone. |

| Pharmaceutical Small Molecules | Rapidly determine the 3D structure of Active Pharmaceutical Ingredients (APIs) directly from reaction mixtures.

|

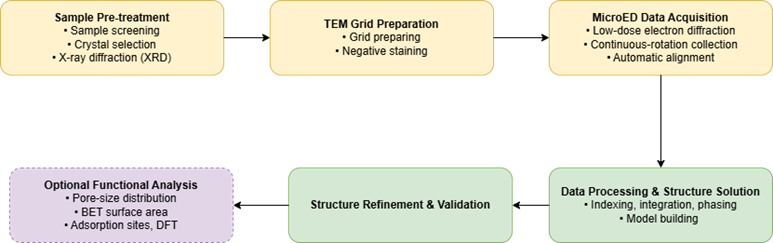

Our Streamlined Workflow from Powder to Patent

We have streamlined the MicroED process to ensure the fastest turnaround time (Standard delivery: 10-15 business days).

1. Consultation & Screening

You send the sample; we perform an initial TEM check to evaluate crystal quality and beam tolerance. Note: If crystals are unsuitable, we stop here to save your costs.

2. Sample Preparation

Nanocrystals are deposited on grids. For air-sensitive materials, we utilize inert-gas glovebox loading and vacuum transfer holders to prevent oxidation/hydrolysis.

3. Diffraction Data Collection

Automated collection of tilt-series diffraction patterns using low-dose protocols.

4. Structure Solution & Refinement

Our crystallographers process the reciprocal space data, phase the structure, and refine the atomic model against the diffraction data.

5. Final Reporting

Delivery of the solved structure (CIF format), refinement statistics, and a comprehensive analysis report suitable for supplementary information in top-tier journals.

Figure 2. MicroED Project Workflow. (Creative Biostructure)

Figure 2. MicroED Project Workflow. (Creative Biostructure)

Why Partner with Creative Biostructure?

- Industry-Leading Infrastructure: We operate a state-of-the-art 200 kV Cryo-TEM platform with automated rotation diffraction that consistently achieves atomic resolution down to 0.9 Å.

- Validated Success Record: Our team has executed over 200 research projects with a structure determination success rate exceeding 85% for MOFs and COFs, significantly outperforming traditional X-ray methods.

- Comprehensive Analytical Support: Beyond structural models, we deliver value-added physicochemical insights including BET surface area calculations and DFT electronic structure analysis to fully validate your material properties.

- Flexible & Secure Engagement: We provide strictly confidential IP protection protocols alongside adaptable pricing models tailored to support both single-crystal academic pilots and large-scale industrial portfolios.

Frequently Asked Questions

Q1: My MOF is extremely sensitive to the electron beam. Can you solve it?

Yes. This is our specialty. We utilize Cryo-EM techniques (cooling the sample to liquid nitrogen temperatures) combined with ultra-fast continuous rotation data collection. This minimizes radiation damage, allowing us to capture high-resolution data before the crystal lattice degrades.

Q2: Do I need to crystallize my sample specifically for MicroED?

Generally, no. If you have a powder that looks crystalline under a light microscope (or shows peaks in Powder XRD), it is likely suitable. We work with the "dust" that remains on the sides of your reaction vial.

Q3: How does this compare to Powder X-ray Diffraction (PXRD)?

PXRD collapses 3D data into 1D peaks, leading to peak overlap and ambiguity in complex structures. MicroED preserves the 3D diffraction spots, allowing for ab initio structure determination rather than just "fingerprinting" known structures.

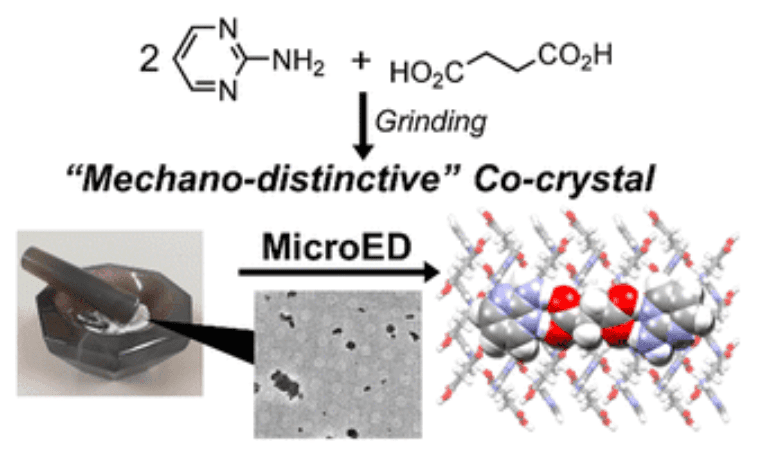

Case: MicroED Unlocks "Mechano-Distinctive" Co-Crystal Structures Inaccessible via Solution

Background

A specific 2:1 co-crystal of 2-aminopyrimidine (2AP) and succinic acid (SA) could only be synthesized via mechanical grinding, yielding micro-powders unsuitable for Single-Crystal X-ray Diffraction (SCXRD). Traditional solution methods failed, consistently reverting to a thermodynamic 1:1 form, leaving the 2:1 structure unsolved.

Methods

MicroED was applied directly to the ground powder using ultra-low dose Cryo-TEM at 79 K. Diffraction data from 14 individual nanocrystals were merged to achieve a complete ab initio structure solution.

Results

- Structure Solution: MicroED resolved the atomic structure, revealing a unique metastable hydrogen-bonding network distinct from the stable 1:1 form.

- Mechanism Revealed: Lattice energy calculations based on the MicroED model confirmed the 2:1 form is less stable (-125.47 kcal/mol) than the 1:1 form, explaining why it cannot grow in solution.

Conclusion

MicroED is the only viable tool for characterizing "mechano-distinctive" materials. It enables the validation and IP protection of novel solid-state forms that are physically impossible to crystallize using standard techniques.

Figure 3. MicroED Structure Determination of a Mechanochemically Synthesized Co-Crystal. (Sasaki T, et al., 2023)

Figure 3. MicroED Structure Determination of a Mechanochemically Synthesized Co-Crystal. (Sasaki T, et al., 2023)

Creative Biostructure promises to work closely with our customers to provide tailored EM strategies for the New‑Material. MicroED provides an efficient and reliable structural analysis platform for new‑material discovery, performance optimization, and patent strategy. Please feel free to contact us for a detailed quote.

References

- Huang Z, Willhammar T, Zou X. Three-dimensional electron diffraction for porous crystalline materials: structural determination and beyond. Chemical Science. 2021, 12(4): 1206-1219.

- Sasaki T, Nakane T, Kawamoto A, et al. Microcrystal electron diffraction (MicroED) structure determination of a mechanochemically synthesized co-crystal not affordable from solution crystallization. CrystEngComm. 2023, 25(3): 352-356.