Mempro™ Liposome Preparation by Extrusion

Creative Biostructure offers a wide range of liposomal products and services based on our magic Mempro™ Liposome platform. Featured Mempro™ Liposome Preparation services including various mechanical and non-mechanical methods are available to meet the custom requirements, and extrusion method is one of our core preparation services.

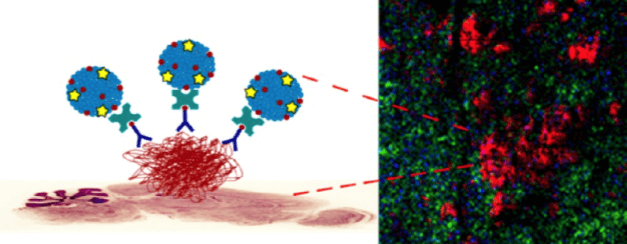

Figure 1. Schematic presentation of the protein detection process. It shows that an amyloid-β deposit binds to biotinylated liposomes prepared by extrusion technique, neutravidin and biotinylated antibodies in a tissue section. ToF-SIMS overview image of the hippocampal region of a transgenic AD mouse brain section is used to visualize liposomes and cholesterol in red and green, respectively. (L. Carlred, et al., 2014)

Figure 1. Schematic presentation of the protein detection process. It shows that an amyloid-β deposit binds to biotinylated liposomes prepared by extrusion technique, neutravidin and biotinylated antibodies in a tissue section. ToF-SIMS overview image of the hippocampal region of a transgenic AD mouse brain section is used to visualize liposomes and cholesterol in red and green, respectively. (L. Carlred, et al., 2014)

In order to reduce the liposome size, multiple extrusions through a polycarbonate membrane can be used. Both of the number of extrusion cycles and the size of membrane pores will determine the degree of size reduction. More...

Temperature, the applied pressure, the size of the pores and the flow rate are crucial factors to influence the extrusion and membrane homogenization. Lipids in the gel-liquid phase are very hard to be extruded effectively at low pressures because the interfacial rheological behavior of the lipid membrane is temperature-dependent, therefore, extrusion process requires temperatures above the phase transition. Moreover, the decreased size of the capillaries leads to the decreased size of liposomes, and the increased flow rate and pressure. Not all filter materials are suitable for extrusion due to the high pressure applied across the membrane, while polycarbonates have been used with success.

Crucial factors:

- extrusion cycles;

- size of membrane pores;

- temperature;

- the applied pressure;

- the flow rate.

Advantages:

- no residual organic solvent or detergents;

- the process has great compatibility to various lipids;

- excellent membrane homogenization in size distribution;

- higher encapsulation efficiencies compared to thin-film method.

Manufacture Features:

- high grade stainless steel equipment, no moving parts;

- easily controlled particle size;

- high trapping efficiencies;

- custom lipid compositions;

- low costs;

- easy-to-use.

Besides extrusion method, Creative Biostructure also offers other liposome preparation services based on our comprehensive Mempro™ Liposome platform. Our rich-experienced research team is confident to provide you the best products and services. Creative Biostructure will be your reliable and professional research associate. Please feel free to contact us for a detailed quote.

References:

T. Lajunen, et al. (2016). Indocyanine Green-Loaded Liposomes for Light-Triggered Drug Release. Mol. Pharmaceutics, 13: 2095−2107.

L. Carlred, et al. (2014). Simultaneous Imaging of Amyloid-β and Lipids in Brain Tissue Using Antibody-Coupled Liposomes and Time-of-Flight Secondary Ion Mass Spectrometry. J. Am. Chem. Soc., 136: 9973−9981.

Z. Cui, et al. (2014). Nonphospholipid Fluid Liposomes with Switchable Photocontrolled Release. Langmuir, 30: 10818−10825.