Cell Free Expression

A cell-free system is an in vitro technology that provides a simplified environment for studying biological reactions and processes that typically occur within living cells. Cell-free systems provide a simplified path by eliminating the complexity and variability of whole-cell interactions. This allows researchers to focus on specific biochemical reactions, molecular interactions, and gene expression mechanisms. This approach is particularly useful for studying protein synthesis, enzyme activity, and metabolic pathways without interference from cellular structures or processes.

At Creative Biostructure, our cell-free expression systems are designed for highly efficient protein production, especially for the manipulation and optimization of membrane proteins (MPs) (cell-free membrane protein expression) for your research and applications.

Introduction to Cell-Free Systems

A cell-free system, also known as a cell-free protein system or cell-free protein synthesis system, or CFPS/CFS for short, is an advanced in vitro technology that enables the study and use of biological responses in a controlled environment outside of living cells. These systems provide an ideal platform for studying cellular processes while avoiding the complexity and unpredictability of whole-cell interactions. By isolating subcellular fractions, often by ultracentrifugation, researchers can extract essential molecular machinery—such as ribosomes, enzymes, and cofactors—that drive specific biochemical reactions. This approach eliminates the need for other cellular components, creating an efficient and versatile framework for both research and industrial applications.

Cell-free systems have evolved significantly since their inception, transforming from a tool primarily used in fundamental research to a robust biomanufacturing technology. They are increasingly being recognized as a cost-effective and scalable alternative to traditional cell-based expression processes.

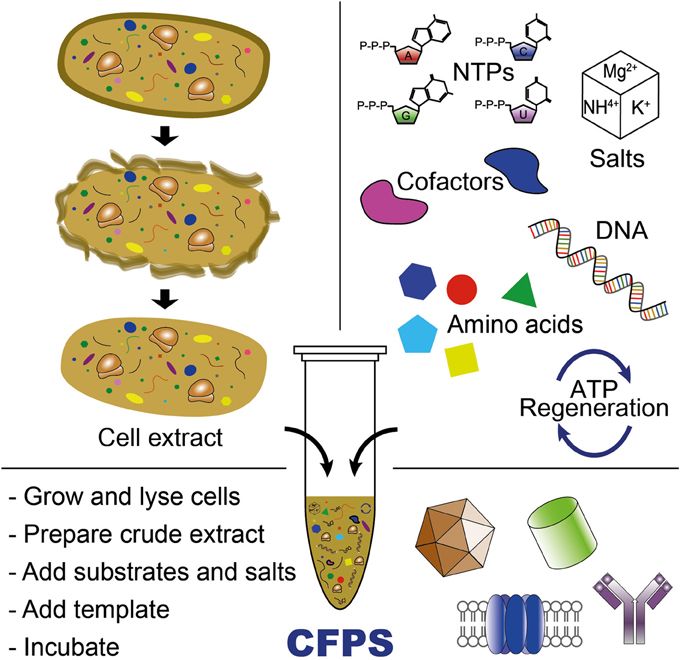

Figure 1. Cell-free protein synthesis system for producing proteins or (poly)peptide-based materials. CFPS requires cell extract, an energy regeneration system, and chemical substrates and salts (e.g., NTPs, amino acids, salts, and cofactors). Cell-free transcription and translation is initiated by adding DNA template (plasmid or PCR-amplified linear DNA templates) into the CFPS reaction. (Hong SH et al., 2014)

Figure 1. Cell-free protein synthesis system for producing proteins or (poly)peptide-based materials. CFPS requires cell extract, an energy regeneration system, and chemical substrates and salts (e.g., NTPs, amino acids, salts, and cofactors). Cell-free transcription and translation is initiated by adding DNA template (plasmid or PCR-amplified linear DNA templates) into the CFPS reaction. (Hong SH et al., 2014)

Principles of Cell-Free Protein Expression

Cell-free protein expression system (CFPS) is based on harnessing the cellular machinery responsible for transcription and translation. It requires key components such as ribosomes, tRNAs, amino acids, nucleotides, ATP, and GTP, along with transcription and translation factors. These components are typically extracted from cells or synthesized chemically.

CFPS involves two main steps:

- Transcription: The DNA template encoding the protein of interest is transcribed into mRNA by RNA polymerase.

- Translation: The mRNA is translated into a protein using ribosomes, tRNAs, and associated factors.

These reactions occur in a buffered solution containing the necessary salts, cofactors, and energy sources to maintain enzymatic activity. The absence of a cellular membrane allows for direct manipulation of the reaction environment and real-time monitoring of protein synthesis.

Preparation of Cell-Free Expression Systems

Cell-free expression systems are developed through the careful assembly of purified enzymes, coenzymes, and other essential molecular components. The preparation process typically involves:

- Extraction of Cellular Machinery: Cellular extracts containing ribosomes, transcriptional and translational machinery, and metabolic enzymes are prepared through mechanical or chemical lysis, followed by ultracentrifugation.

- Addition of Reagents: Key substrates, energy sources (e.g., ATP and GTP), cofactors (e.g., magnesium ions), and amino acids are added to enable specific reactions.

- Optimization for Specific Applications: Depending on the desired application, additional modifications such as the incorporation of synthetic biology tools or engineered enzymes can be made to enhance system performance.

Types of Cell-Free Protein Expression Systems

CFPS systems are broadly categorized based on the source of cellular extracts. The most commonly used systems include:

Prokaryotic Systems

Derived from Escherichia coli lysates, these systems are robust and inexpensive, making them suitable for high-throughput applications. However, they may struggle to produce eukaryotic proteins with complex post-translational modifications (PTMs).

Eukaryotic Systems

- Wheat Germ Extracts: Derived from plant embryos, these systems are effective for synthesizing eukaryotic proteins but may lack certain mammalian PTMs.

- Rabbit Reticulocyte Lysates: Rich in translation machinery, these extracts are suitable for producing eukaryotic proteins with functional activity.

- Insect Cell Extracts: Capable of producing proteins with PTMs similar to those found in mammalian cells. For example, this system can be used to produce virus-like particles (Mempro™ virus-like particles (VLPs) production in insect cells system).

Mammalian Systems

These systems, such as those derived from human (HeLa cells) or Chinese hamster ovary (CHO) cells, are engineered to produce proteins with native PTMs and are preferred for therapeutic protein development.

Hybrid Systems

By combining elements from different sources, hybrid systems seek to optimize protein yield and functionality.

Comparison of cell-free protein expression systems

| E. Coli cell lysate | Rabbit reticulocyte cell lysate | Hela cell lysate | CHO cell lysate | |

| Yield | High | Low | Medium-high | High |

| Protein modifications | None | Limited glycosylation | Glycosylation and phosphorylation | Glycosylation and phosphorylation |

| Recommended for high MW proteins | No | No | Yes | Yes |

| Produces functional proteins | Possible | Possible | Yes | Yes |

| Comments | Robust system | Flexible system | Higher protein yield per reaction | Most economocal cost per miligram produced |

Applications of Cell-Free Systems

Membrane Protein Production

Cell-free expression provides an advanced platform for the efficient production of membrane proteins (MPs) (Cell-free membrane protein expression), which are important targets in pharmaceutical research. Membrane proteins are involved in many critical biological processes, making them essential for drug discovery. CFPS provides a controlled and simplified environment where the entire protein synthesis process can be directly monitored, ensuring the production of functional and soluble membrane proteins.

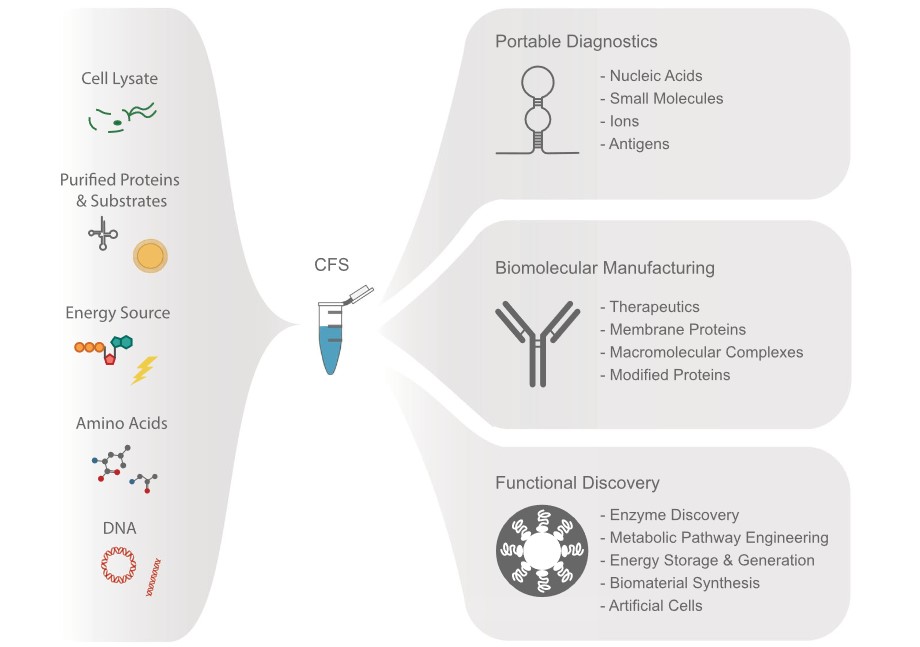

Portable Diagnostics

Cell-free expression systems have revolutionized portable diagnostics by enabling rapid on-site detection of pathogens, biomarkers, or genetic sequences. These systems eliminate the need for live cells and complex laboratory infrastructure, making diagnostics feasible in remote or resource-limited settings. They can be lyophilized for stability and rehydrated as needed, providing a robust platform for rapid and sensitive detection. For example, cell-free systems are used in paper-based diagnostic assays for diseases such as Zika or COVID-19, where RNA or DNA amplification and protein expression occur directly in the device.

Biomolecular Manufacturing

In biomolecular manufacturing, cell-free systems allow the production of proteins, enzymes, or other biomolecules without the constraints of cellular growth and maintenance. This approach accelerates the production process and provides precise control over the expression environment. Applications range from the production of therapeutic proteins and vaccines to the synthesis of industrial enzymes or bioactive compounds. In addition, cell-free systems can be engineered to produce complex biomolecules, including those that are toxic or unstable in living cells, with high yields and efficiency.

Functional Discovery

Cell-free expression facilitates functional discovery by enabling high-throughput screening of genes and their encoded proteins. Researchers can study enzyme activity, protein-protein interactions, or regulatory elements in a simplified and controlled environment, bypassing the challenges of cellular complexity. This system is especially valuable in synthetic biology and metabolic engineering, where rapid prototyping and optimization of genetic circuits or metabolic pathways are required. It also allows for direct observation of transcription and translation processes, aiding in fundamental research and innovation.

Figure. 2: Cell-free protein expression systems and their applications. Capitalizing on their open nature, CFS can be rationally assembled to include cell lysates, purified proteins, energy sources (e.g., ATP), amino acids, other substrates (such as modified tRNAs and membrane mimics) and RNA or DNA (circular or linear). CFS can be applied in portable diagnostic devices and also hold great potential for biomolecular manufacturing. Additionally, CFS can enable discovery of novel enzymes (e.g., through directed evolution). (Tinafar A, et al., 2019)

Figure. 2: Cell-free protein expression systems and their applications. Capitalizing on their open nature, CFS can be rationally assembled to include cell lysates, purified proteins, energy sources (e.g., ATP), amino acids, other substrates (such as modified tRNAs and membrane mimics) and RNA or DNA (circular or linear). CFS can be applied in portable diagnostic devices and also hold great potential for biomolecular manufacturing. Additionally, CFS can enable discovery of novel enzymes (e.g., through directed evolution). (Tinafar A, et al., 2019)

Advantages and Limitations of Cell-Free Protein Expression

The cell-free expression system offers several distinct advantages over traditional cell-based protein expression systems. Despite its advantages, CFPS has limitations that must be addressed for broader adoption:

| Advantages of Cell-Free Protein Expression | |

| Speed | CFPS bypasses the need for cell growth, enabling rapid protein production, often within hours. |

| Versatility | CFPS can express a wide range of proteins, including toxic or unstable proteins that are difficult to produce in vivo. |

| Open System | The reaction environment is accessible, allowing for real-time modifications, isotope labeling, and incorporation of non-natural amino acids. |

| High Throughput | CFPS is amenable to automation and miniaturization, facilitating large-scale screening applications. |

| Simplified Process | CFPS eliminates the complexities of cell culture and purification associated with in vivo systems. |

| Limitations of Cell-Free Protein Expression | |

| Cost | Extraction of cellular components and preparation of reaction mixtures can be expensive compared to cell-based systems. |

| Limited Yield | Protein yields in CFPS are generally lower than those achievable in high-density cell culture. |

| Post-Translational Modifications | While eukaryotic CFPS systems can perform some PTMs, they may not fully replicate the complexity of modifications found in vivo. |

| Stability | The reaction components have limited stability, which can affect the duration and efficiency of protein synthesis. |

In summary, cell-free systems represent a transformative approach to the study and exploitation of biological reactions. Their unique advantages, including ease of control, high product yields, and compatibility with diverse reaction conditions, position them as a powerful tool in modern biomanufacturing.

At Creative Biostructure, we offer advanced platforms for high-quality, reliable cell-free protein expression customized to meet your specific needs. Contact us today to find the optimal solution for your project!

References

- Hong SH, Kwon YC, Jewett MC. Non-standard amino acid incorporation into proteins using Escherichia coli cell-free protein synthesis. Front Chem. 2014;2.

- Tinafar A, Jaenes K, Pardee K. Synthetic biology goes cell-free. BMC Biol. 2019;17(1):64.